Pearl Ash, Pot Ash, and the Ashery

Pearl Ash, Pot Ash, and the Ashery

.

A short while ago, I shared a blog article about Victorian-era leavening: baking soda, baking powder bicarbonate of soda, soda ash, and the all-mysterious saleratus. I touched on pearl ash (another ingredient to make bread or cake rise)–obtained by soaking fireplace ashes in water to make lye. This is so bizarre! Who knew? I’m uncommonly enamored with all things nineteenth century, and I had no idea. Let me share with you a bit more about the importance of ashes in the nineteenth century United States.

.

.

![]()

.

VALUE OF POTASH

.

“As early as 1767, potash from wood ashes was exported from Canada, and exports of potash and pearl ash (potash and lime) reached 43,958 barrels in 1865. There were 519 asheries in operation in 1871. The industry declined in the late 19th century when large-scale production of potash from mineral salts was established in Germany.”

.

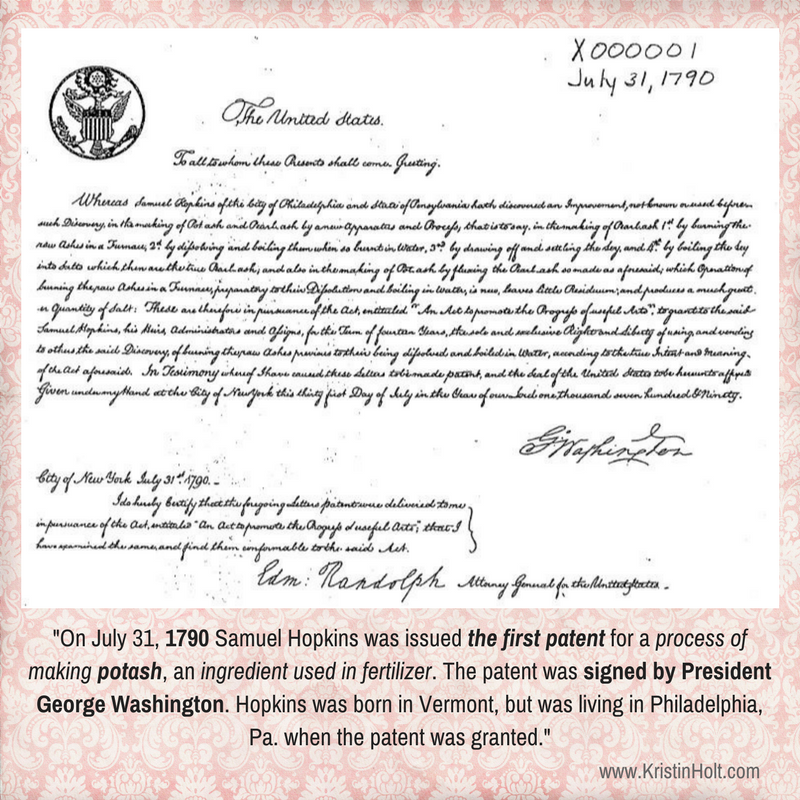

FIRST U.S. PATENT (Literally #1)

.

Quote at the bottom of this image, referencing the first patent for the process of making potash (and signed by President George Washington), is from the United States Patent and Trademark Office. Patent Image: First U.S. Patent, for Potash. Dated 1790. Credited to Wikimedia Commons. Public Domain.

.

Pearlash (Potassium Carbonate)

.

On this side of the Atlantic the early colonists were blessed with hardwood forests as far as the eye could see. Aside from being a logical building material and fuel, hardwoods provided another important resource, ashes. Ashes were a major export two hundred years ago, both to Canada and Britain. They were valuable for sweetening gardens and providing lye for making soap. They were also a source of potash and its derivative, pearlash, another creative leavening agent.

.

To make pearlash, you first have to make potash which itself is made from lye. aTo make lye, you pass water through a barrel of hardwood ashes over and over until an egg can float on the residue. (To make soap you boil this lye water with lard or other fat until it is thick, pour it into molds and harden it into cakes.) aTo make potash, you evaporate lye water until you have a solid.

.

Pearlash is a purified version of potash. It is an alkaline compound which will react with an acidic ingredient such as sour milk, buttermilk or molasses to produce carbon dioxide bubbles, the very same thing that yeast produces. Pearlash was used primarily in the seventeenth and eighteenth centuries but because of its bitter aftertaste, it not only did not replace yeast but was eventually replaced by saleratus.

.

Saleratus (Potassium Bicarbonate or Sodium Bicarbonate)

.

Saleratus (aerated salt) is an old word for modern baking soda. It actually was used as a name for both of the above compounds, but, like pearlash, potassium bicarbonate had an unpleasant aftertaste and fell out of use early in the nineteenth century. So saleratus came to mean just sodium bicarbonate (bicarbonate of soda) itself. You’ll find it in nineteenth century recipe books used just as baking soda is used today.

.

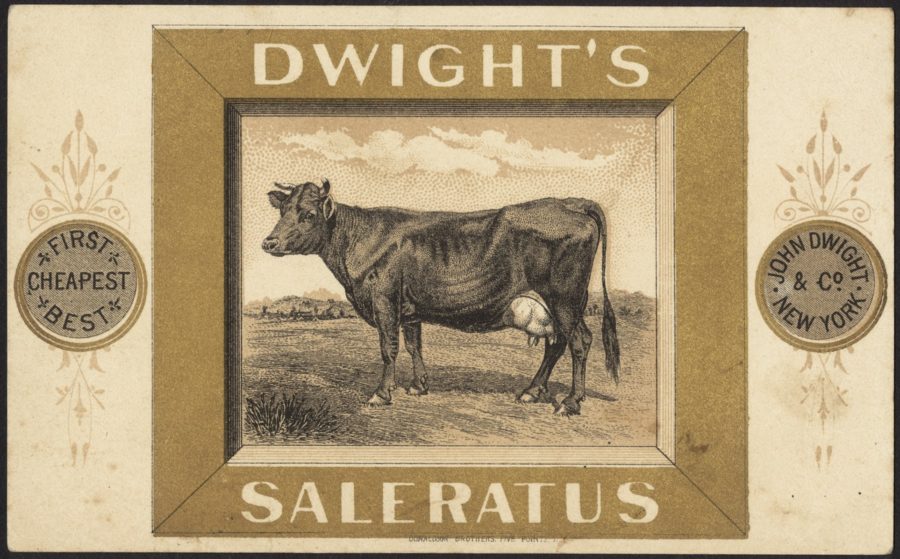

Saleratus was first sold on this side of the Atlantic by John Dwight, who, with his brother-in-law, Dr. Austin Church, started manufacturing it in their kitchens. It was called Dwight’s Saleratus with a cow as a trademark because of the necessity of using sour milk to activate it in baking. (emphasis added)

.

.

Dwight’s Saleratus, Part 1. Images: Digital Commonwealth, Massachusetts Collections Online, No Copyright.

.

Dwight’s Saleratus, Part 2. Images: Digital Commonwealth, Massachusetts Collections Online, No Copyright.

.

![]()

.

PEARL ASH, in BAKING

.

In late 18th century North America, before the development of baking powder, pearl ash was used as a leavening agent in quick breads.

.

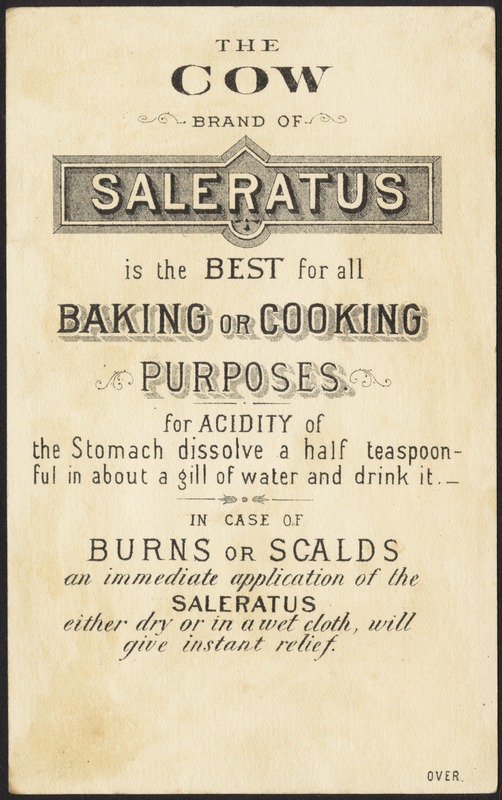

~ Wikipedia.org, Potassium carbonate referencing the use of “pearl ash” in “American Cookery” by Amelia Simmons, 1796.

.

Title page of “American Cooke“ by Amelia Simmons. Published 1796. Image: Library of Congress.

.

The first published recipe to call for pearlash (a type of gingerbread) was published in 1796 by one Amelia Simmons. It was the beginning of a chemical leavening revolution that would spread around the world. ~ Joe Pastry

.

![]()

.

Ashery

.

An ashery is a factory that converts hardwood ashes into lye, potash, or pearlash. Asheries were common in newly settled areas of North America during the late 18th century and much of the 19th century, when excess wood was available as settlers cleared their land for farming. Hardwood ashes contain abundant levels of potassium carbonate and potassium hydroxide, the principal components of the products being produced.

.

Lye was produced by soaking ashes in hot water, filtering out the ashes, and repeating with fresh ashes as necessary to obtain the desired alkalinity in the resulting liquid. This liquid, commonly called lye could then be mixed with fats to produce soft soap, or it could be evaporated (often by boiling) to produce pot ash or black salts which still contained dark carbon impurities. The potash could then be baked in a kiln to further refine the substance into a pearly white material called pearl ash, pearl-ash or pearlash.

.

The lye and potash stages were commonly performed on site by the settlers themselves, and the asheries only performed the final step and most difficult step of converting the black salts to pearlash.

.

The product was often shipped to Great Britain where it was used in the production of glass and ceramic wares.

.

.

![]()

.

PICTURING AN ASHERY

.

Deseret News online published images of a rebuilt 19th century ashery on April 26, 2017. “Free tours giving insight into how the ashery was operated are available to visitors.”

.

The ashery may be the only such rebuilt structure in the United States.

.

.

The original ashery, constructed in Kirtland, Ohio by Newel K. Whitney (second bishop of The Church of Jesus Christ of Latter-day Saints), built in 1823-24.

.

“The rebuilt ashery in Kirtland, Ohio.” Image copyright © Kenneth Mays. Published on Deseret News.com, title: Picturing history: The ashery in historic Kirtland. Published April 26, 2017.

.

“A (second) interior view of the rebuilt ashery in Kirtland, Ohio.” Image copyright © Kenneth Mays. Published on Deseret News.com, title: Picturing history: The ashery in historic Kirtland. Published April 26, 2017.

.

![]()

.

Related Articles

.

And because Remebrance’s father turns to the hardwood forest for the value of ashes…

.

![]()

.

Updated September 2021

Copyright © 2018 Kristin Holt LC

Pearl Ash, Pot Ash, and the Ashery Pearl Ash, Pot Ash, and the Ashery